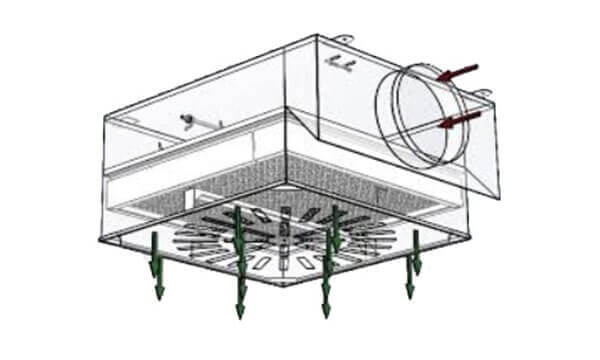

HEPA FILTER BOX

HEPA filter boxes are designed for the airtight installation of HEPA

filters used at the final air outlet in cleanrooms, laboratories, operating rooms,

hospitals, the chemical and pharmaceutical industries, the food industry, and hygienic

ventilation systems. Air is typically distributed into the room through HEPA filter boxes.

Accurate selection and leak-proof installation are crucial.

The HEPA filter box consists of 3 main components: body, filter, and diffuser. The body

includes a duct connection for top or side air intake, depending on preference. The bottom

face (facing the room) can be fitted with a perforated or louvered diffuser for air

distribution. The fully welded main body is leak-proof to comply with hygienic requirements.

The filters are easy to mount and dismount.

Pressure differential (filter clogging) test outlets are standard on all HEPA boxes. Filters

can range from class E10 to U16, depending on the cleanroom requirements. The weight of the

HEPA boxes varies between 12 kg and 47 kg based on dimensions and construction. All HEPA

boxes undergo a sealing (gasket) test.

To monitor filter conditions, the unit includes nozzles for differential manometers.

According to EN 1882 standards, test aerosol (DOP) application nozzles are included at the

H13/H14 filter inlet. The filter seating grooves are designed per DIN 1946 Part 4 to ensure

airtight sealing. A test groove is present for measuring this seal. The interior of the box

is disinfectable and resistant to disinfectant chemicals.

Upon request, the box can be manufactured in various sizes using painted DKP sheet metal or

stainless steel.